Wood fired shaft kilns produced lime products in Wisconsin for nearly 100 years. In the latter years of their life span, operators of these plants looked for ways to increase production while saving costs. The plant at Nasbro, Wisconsin was no exception. The operational changes can be readily seen by close examination of two of the kilns at the Nasbro plant prior to its’ closure in the late 1980’s.

Wood was the primary fuel for these plants through most of their operating history. At first, most of the wood was supplied by local sources, but as the nearby sources dwindled, most of the wood was shipped in from northern Wisconsin.

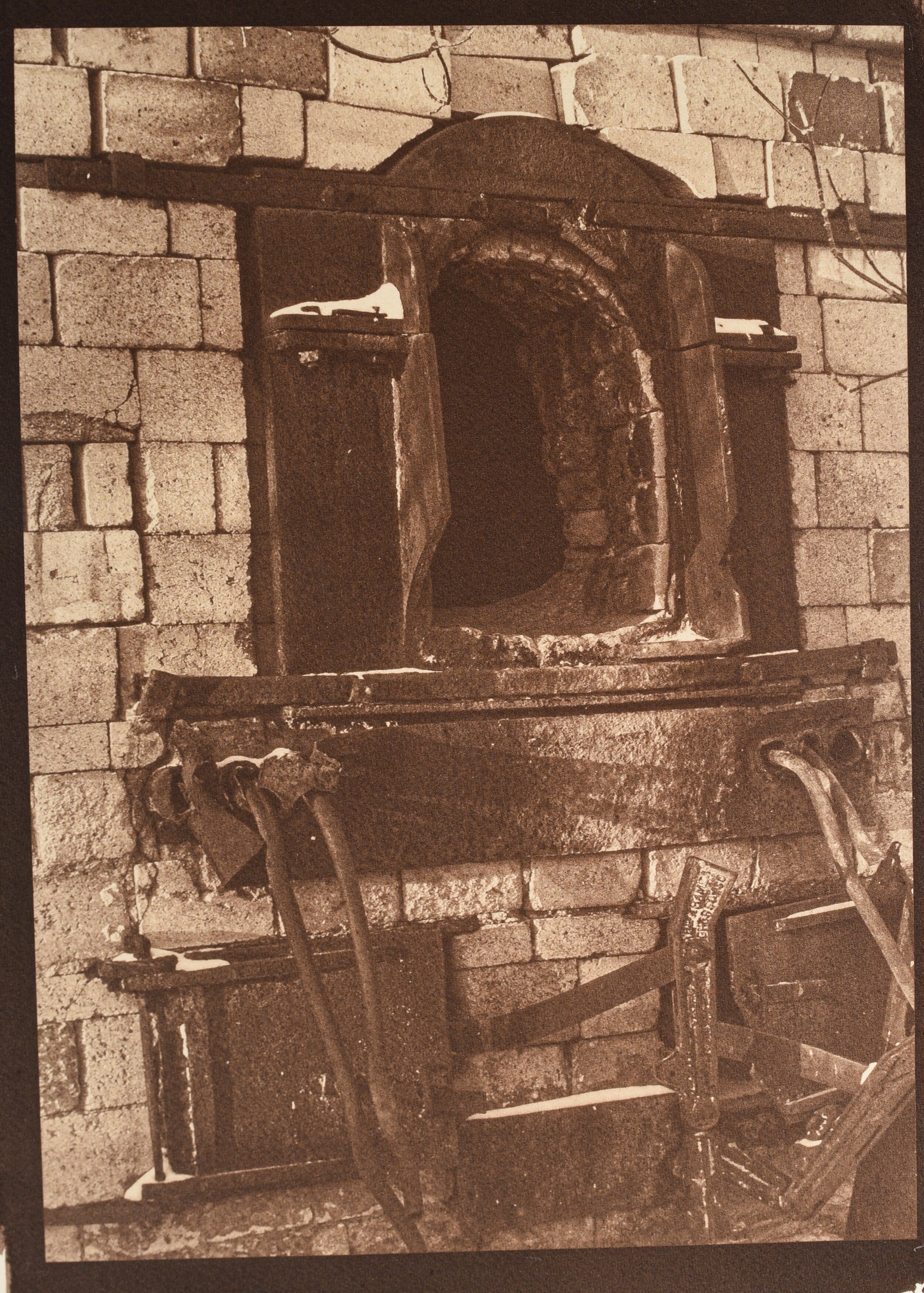

At Nasbro, wood was eventually replaced by gas for ‘cooking’ the lime. Evidence of this can be seen by the addition of gas lines into the openings where wood was used to stoke the fires.

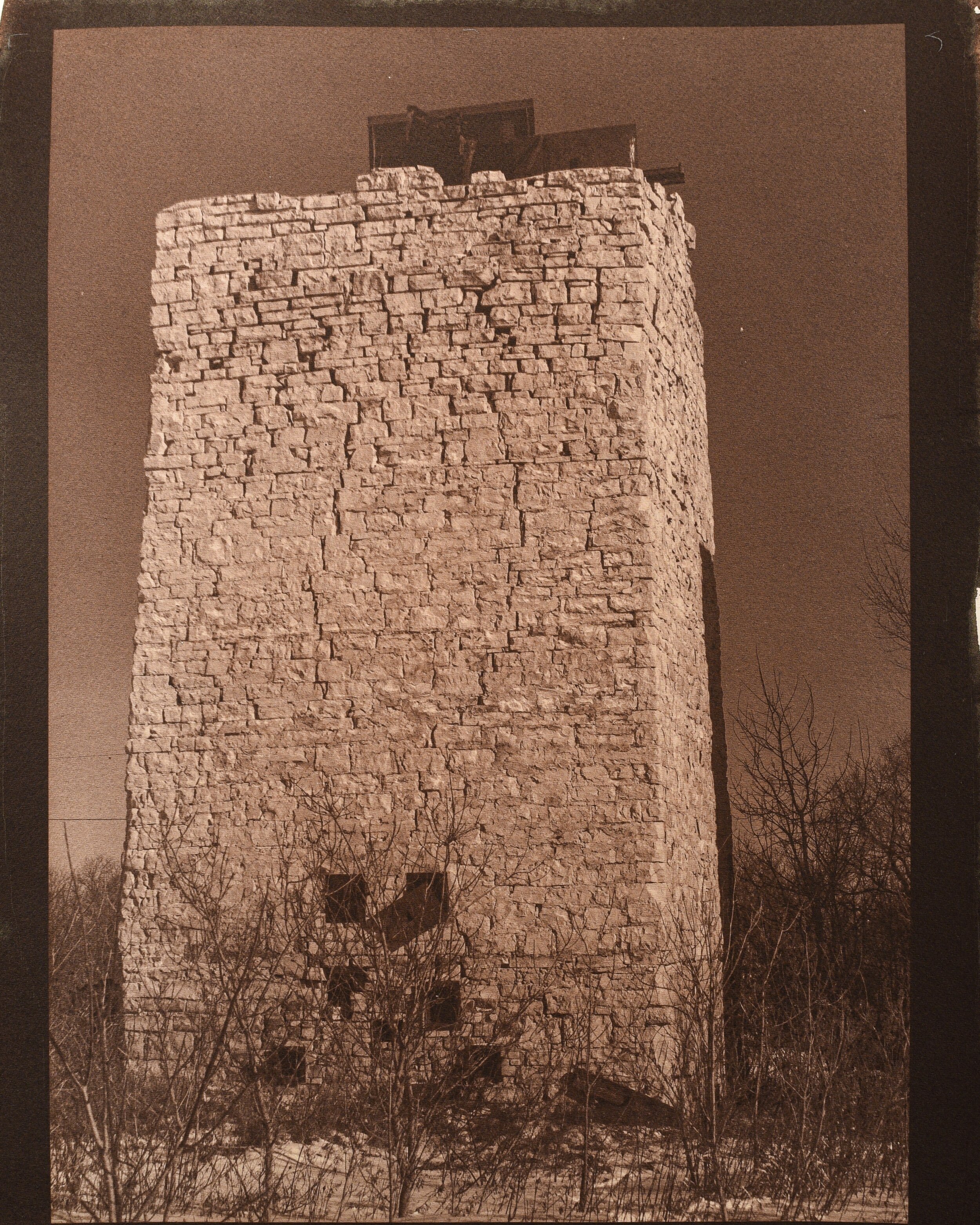

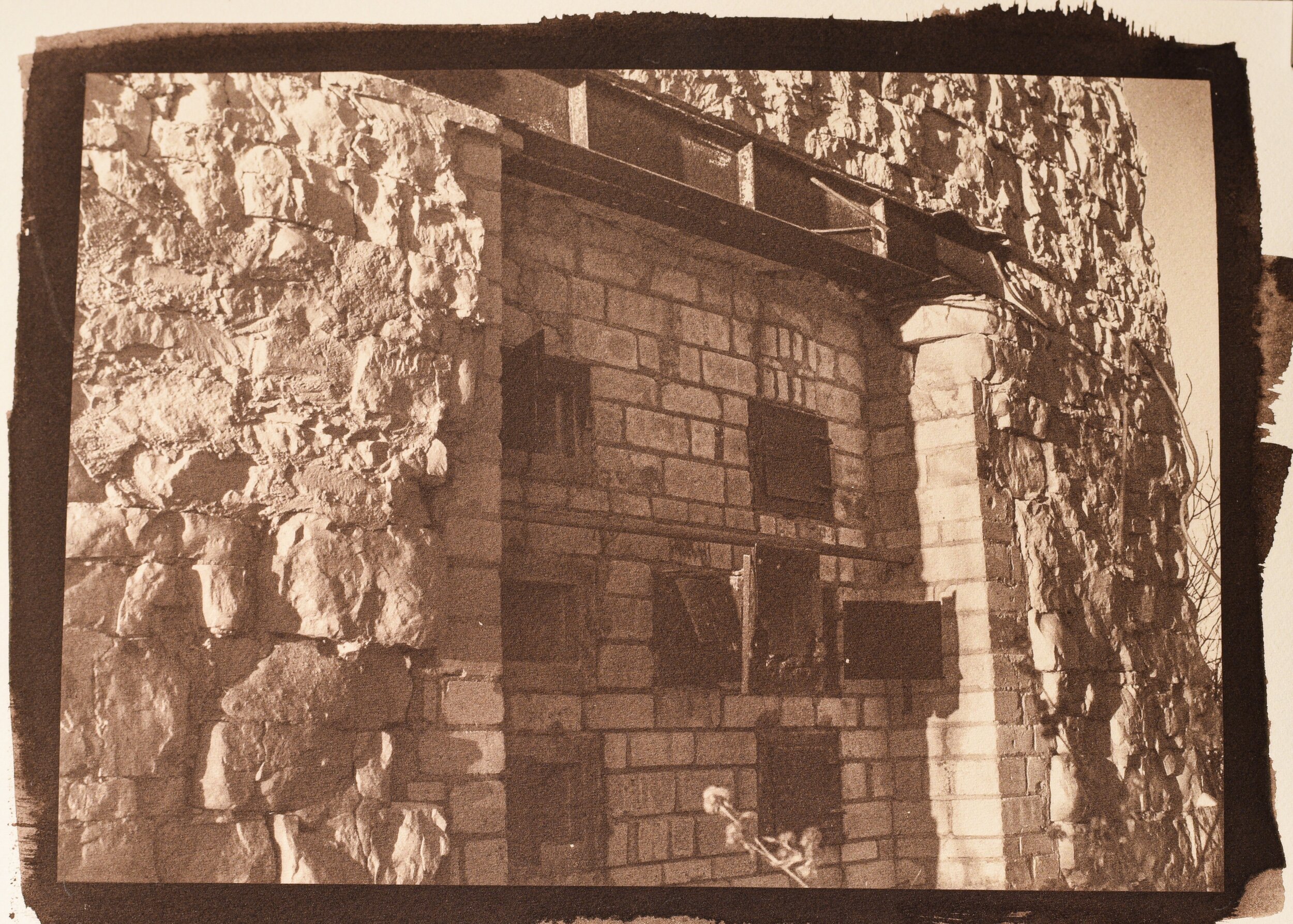

According to Duey Valle, a 25 year veteran of Western Lime, significant modifications were made to Nasbro kilns 1 and 2. In the early 1970’s, covers were installed on these two kilns along with blowers to keep hot air circulating in the kiln. These were known as ‘fast firing’ kilns. The doors on the kiln tops (still visible) would keep the hot air in the shaft thereby speeding up the process of producing lime. The workers would close the lids and start the blowers when not filing the kiln.

Instead of taking a lime ‘draw’ every four hours, these fast firing kilns reduced the time between draws to two hours. The workers did not like these kilns because it was a lot more work putting in more stone and taking more frequent draws.

The exteriors of the two fast firing kilns bear more evidence in changes to how these kilns operated. Additional exterior opening were added, either on the back side of the kiln, or in the place of one of the older wood firing doors. These tended to be smaller, metal lined openings with small exterior doors. The purpose of these opening is not clear. It is possible that these were poke holes that the workers could use to help the lime rock through the firing zone. Or perhaps there were used to regulate the firing temperatures.

Eventually, the decision was made to cease operations at Nasbro in the late 1980’s.. Many of the workmen were relocated to the plant at nearby Marblehead where a new rotary kiln had begun operation. With the shutdown of the kiln operations, the small company town of Nasbro was gradually abandoned, leaving little trace of its existence.