Records of lime kiln operation prior to the 1880’s when larger, industrial plants formed in part due to the presence of railroad shipping, are not very common. Not many of these small kilns remain today. Even more uncommon are pictures of them, and even rarer are images of them in operation.

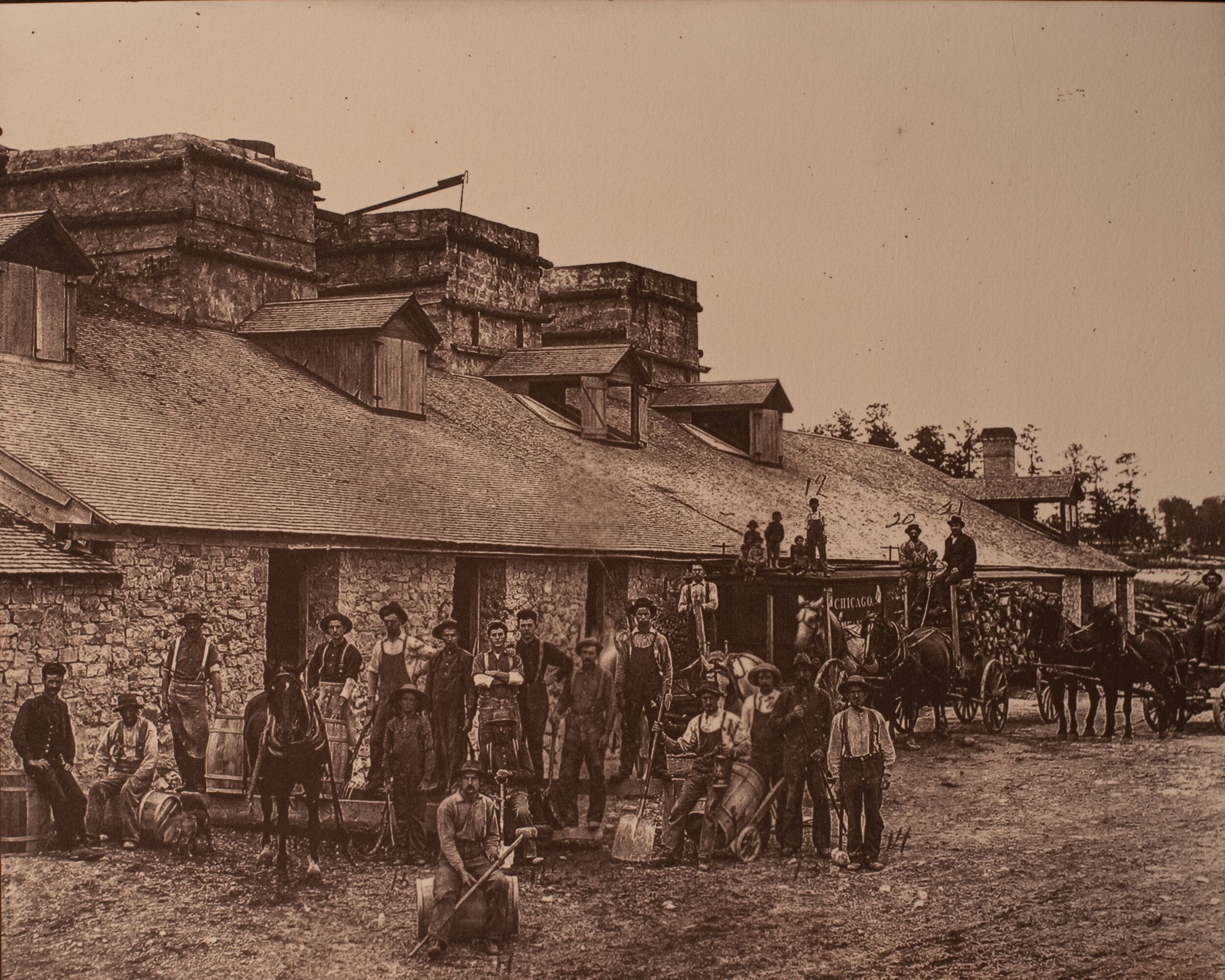

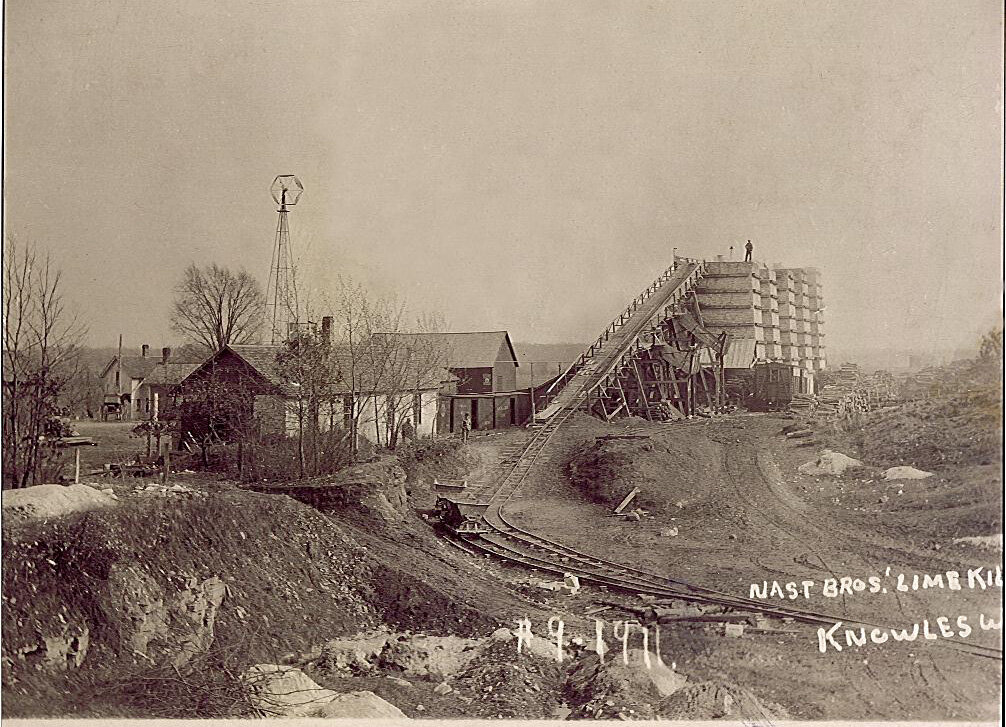

C. Muloch Lime Kiln 1882

Here is an image of an early lime production at a small family enterprise near Rockville in far western Manitowoc County. It is a fascinating image, taken in 1882, of kilns operated by C Muloch. This tells the full story of anb operation. First, note that these are single fire pot kilns. There are at least two of them.It is likely that the man standing on the roof in the left center is C. Mulroch. In front of his sits a block of limestone (probably ‘uncooked’). Above his is a team of horses and a wagon loaded with limestone from a nearby ready to be loaded into the top of the kilns. At the base of one of the structures is another horse drawn wagonb carrying a load of wood used to fire the kiln. On the far right hand of the image is another team of horses with what appears to be the burnt lime. In front of it all are two well dressed women, possibly spouses. In the center is a young child in a wagon being held by what would appear to be th mother.

On the upper left is a barn, likely used to house the horses (and possibly finished product ready for shipment. To the left is a log cabin which may be a house. I feel sorry for anyone living this close to a firing kiln, especially when hanging wash to dry.

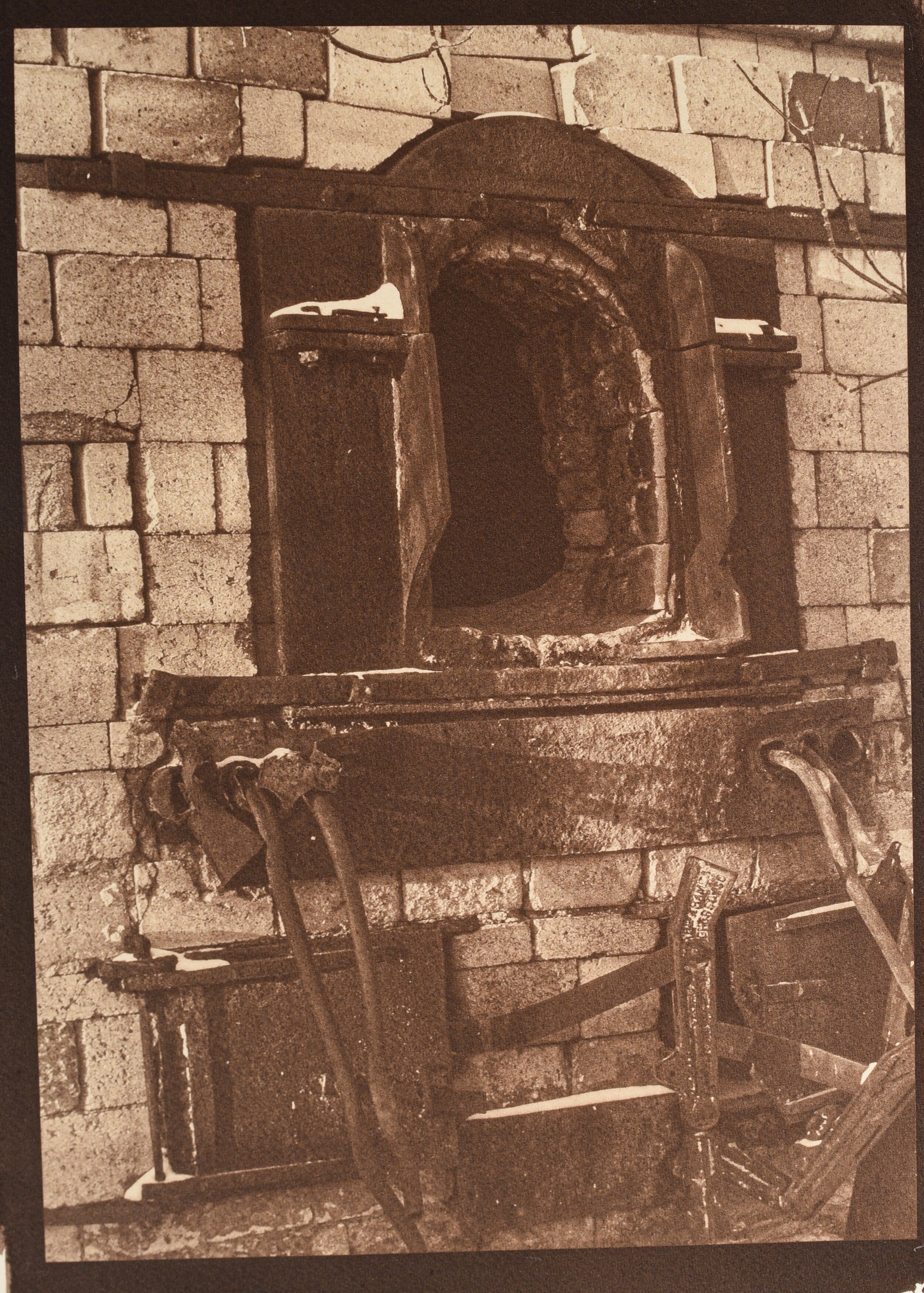

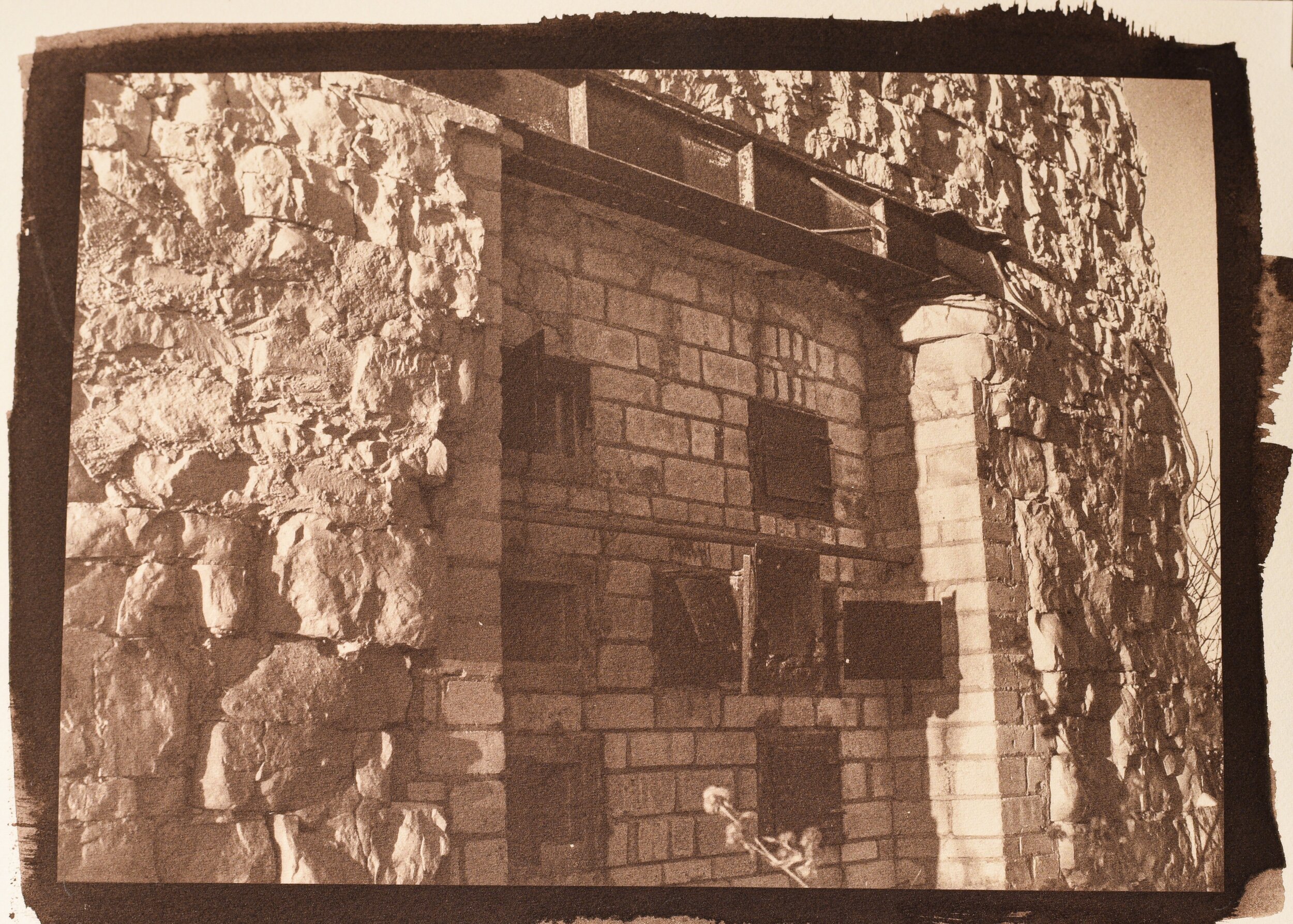

There are two pot kilns, with logs used to support the stone work. Notice that the kiln on the ar right has a roof. This was necessary to keep the lime as dry as possible to prevent it from slaking. The kiln in the middle does not have a roof for some reason, but the opening for removing the cooked lime is clearly visible. The opening is plugged with a wooden door. When firing the kiln, this door was removed, and it was temporarily replaced with rocks or brick to contain the heat and fire.

So how old is this operation. This clearly shows the plant in operation by 1882. In 1878 the property is shown to belong to a J.No kilns were shown on an 1878 plat map, but no lime kiln is listed. In 1892 the plat maps show a kiln at this location on the “Cedar Grove Farm” on land owned by John Rosenbauer. After 1892 no maps show the lime kiln.

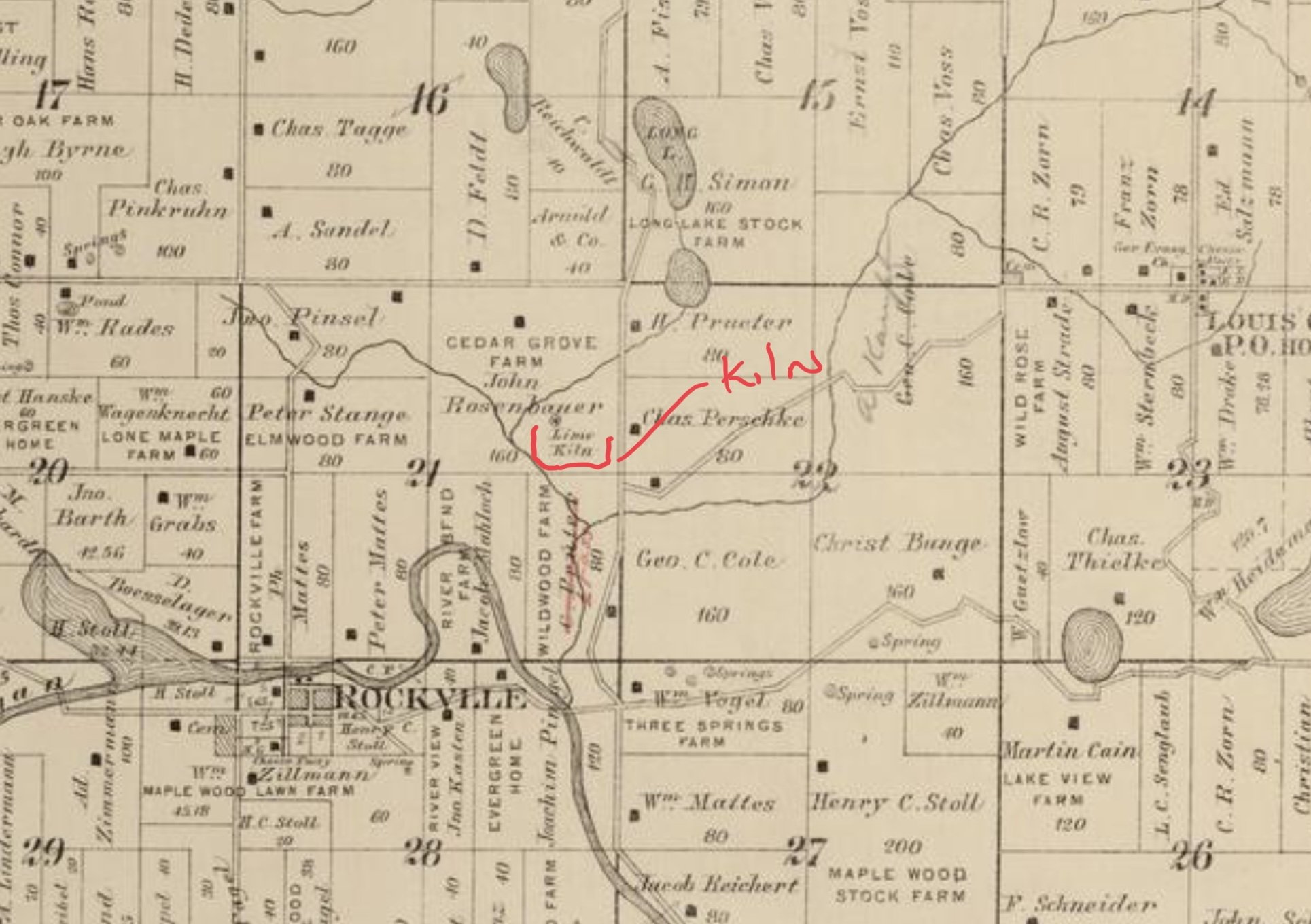

1878 Plat Map showing Muloch parcel

1892 Plat Map showing lime kiln location

So it would appear that this kiln began operation between 1878 and 1882, probably to supply lime for the fast growing town Kiel (just to the west of Rockville). The kilns might in have been in operation in 1892, but probably not under the ownership of the Muloch’s. By the mid 1890’s the railroad had come through Kiel, probably halting operation. Lime could be obtained by nearby plants in Valders or Quarry, where product could be shipped by rail.

As far as I know nothing remains of this kiln, but a trip to the area is planned in the near future.